Products

Grinder

Grinding Mill

Core Working Principle

Grinding mills utilize the principle of “mechanical grinding + frictional crushing.” Through the relative motion of high-speed rotating grinding media (such as grinding discs, grinding balls, and grinding rollers) and the material, they exert squeezing, shearing, and impact forces on the material, reducing bulk and granular materials to micron or even nanometer levels.

Advantages

- High grinding accuracy

- Wide applicability

- Excellent grinding uniformity

- Optional cryogenic grinding

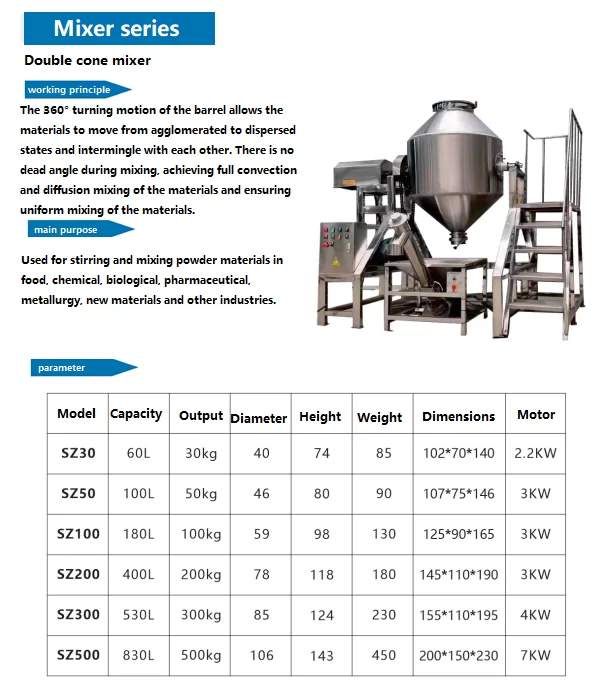

Mixer

A mixer utilizes the dual effects of “forced convection + diffusion mixing.” Its mechanical structure drives material movement, achieving uniform fusion of different components (such as powders, granules, and liquids). Its core function is to disrupt the initial distribution of materials and promote interpenetration and diffusion between components.

Advantages

- High mixing efficiency, significantly saving time.

- High mixing uniformity, eliminating dead spots.

- Compatible with various material forms and flexible application scenarios.

- Easy to clean and meets hygiene standards.

- High controllability and convenient operation.

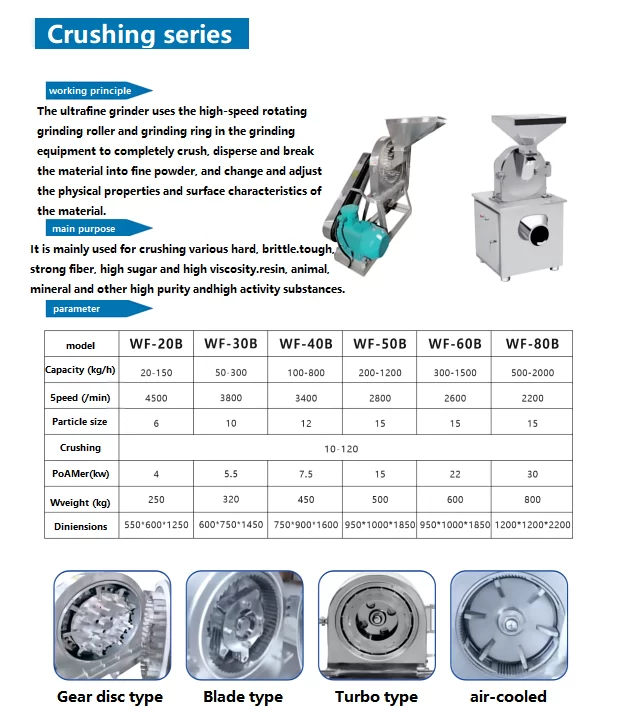

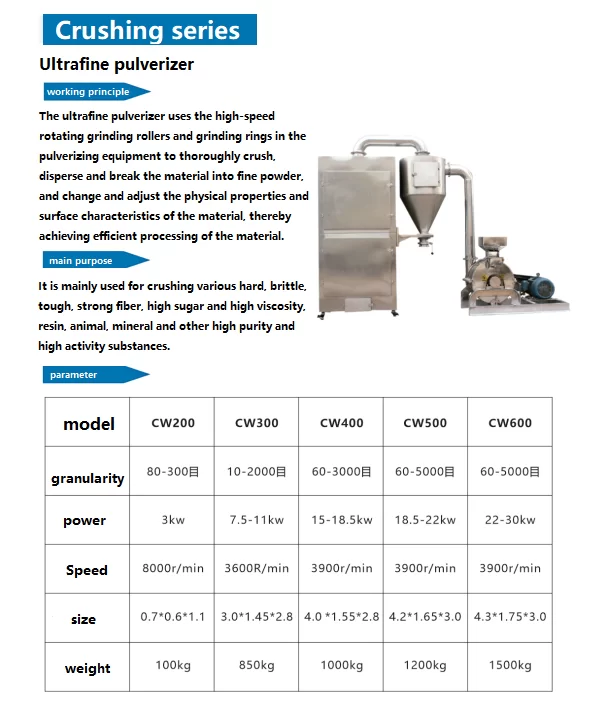

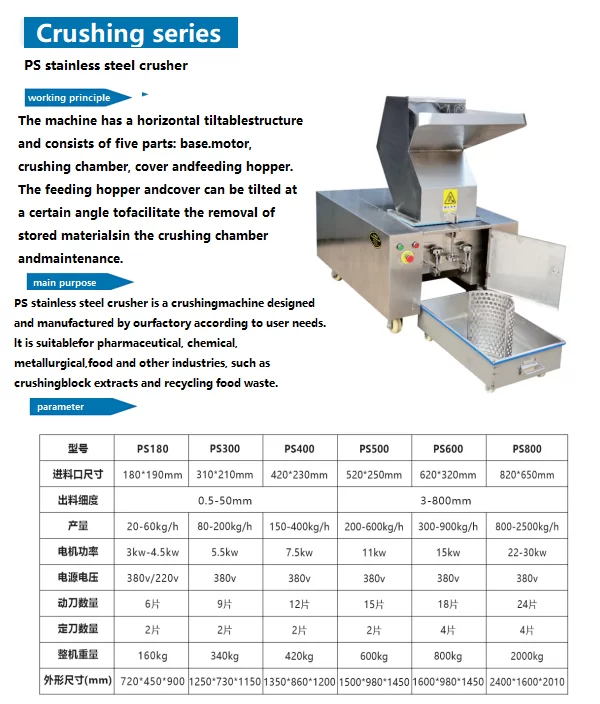

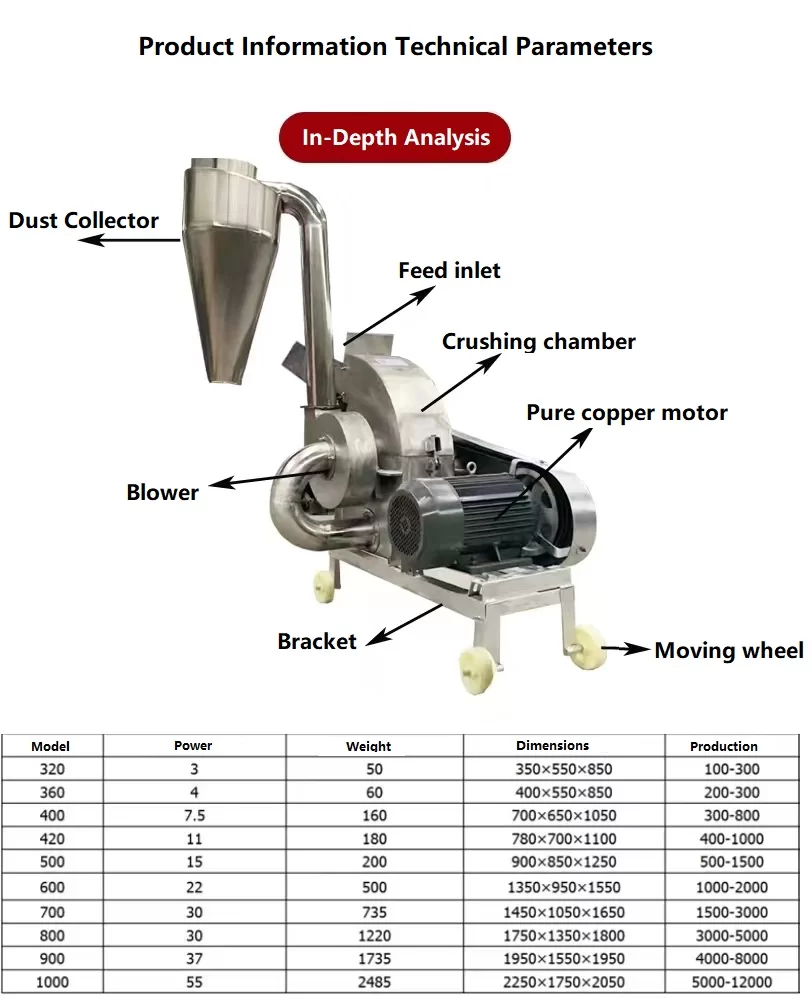

Pulverizer

Principle

Pulverizers utilize the principle of mechanical crushing. High-speed moving core components (such as blades, hammers, grinding discs, and toothed rollers) apply impact, shearing, extrusion, and grinding forces to the material, breaking down the intermolecular bonds and structural integrity of the material, reducing large, coarse particles into fine particles or powders that meet your needs.

Advantages

- Strong refining capability and controllable particle size.

- Wide compatibility, covering a wide range of materials.

- High processing efficiency and flexible production capacity.

- Durable construction and low maintenance costs.

- Easy operation and high safety.